In today’s global marketplace, it feels like the only constant is the unexpected. Tariffs and supply chain disruptions have moved from being occasional headaches to the new normal. While many manufacturers are feeling like they’re navigating a never-ending obstacle course, some forward-thinking companies are realizing that one industry’s turmoil can be another’s springboard for strategic growth and supply chain optimization.

If your manufacturing operations haven’t been hit as hard by the current trade tensions and supply chain bottlenecks, this period could be your golden ticket to market expansion – but only if you’re geared up and ready to seize the moment.

Before you hit the gas on manufacturing scalability, successful manufacturers are taking a breath and focusing on five crucial areas. Think of these as the hidden keys that unlock sustainable growth amidst the uncertainty. Mastering these can transform supply chain chaos from a threat into your company’s ultimate competitive edge.

1. Enterprise Resource Planning (ERP) System Optimization: Your Operational Command Center

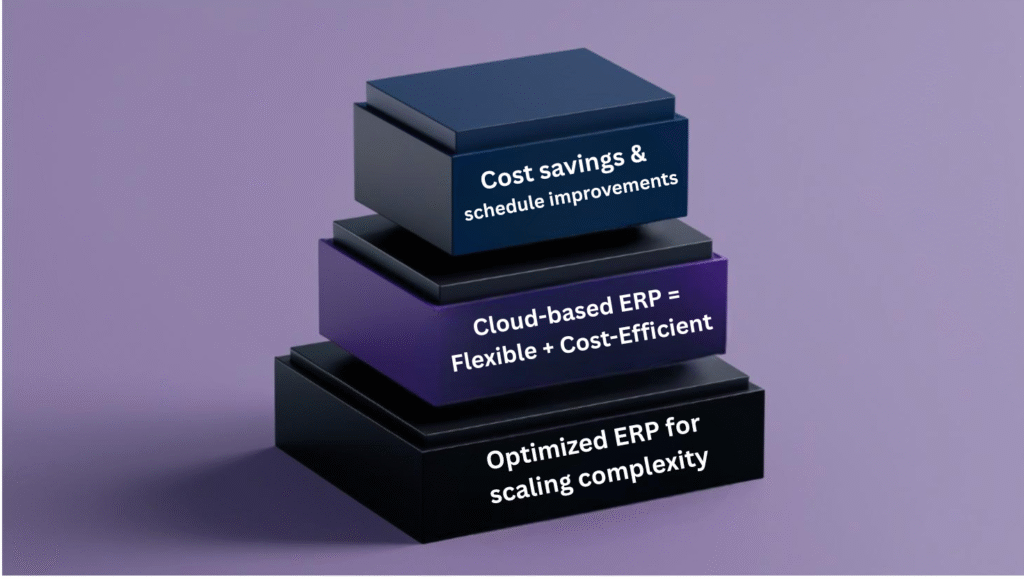

Imagine trying to run a marathon without knowing where the water stations are. That’s what scaling without an optimized ERP system for manufacturers feels like. Your ERP system is the central nervous system of your manufacturing operations, the backbone that holds everything together. Before you even think about adding more production lines or venturing into new markets, take a good look under the hood of your current ERP system infrastructure. Can it handle the increased complexity?

Modern cloud-based ERP systems for manufacturers are like the superheroes of manufacturing scalability, offering the flexibility to expand your operations without needing a bank vault full of capital investments.

Key questions to ask yourself:

- Does your ERP system provide a real-time, crystal-ball-like view across all your operations?

- Can it seamlessly integrate new facilities, suppliers, or distribution channels without a major headache?

- Does it offer predictive analytics to anticipate your resource needs as you grow?

Companies that invest in fine-tuning their ERP system for manufacturers before they scale report a 32% reduction in operational costs and a 23% improvement in production schedule compliance. It’s like having a well-oiled machine that not only runs smoothly but also anticipates your next move.

2. Process Mining Implementation: Unearthing Hidden Gold in Your Operations

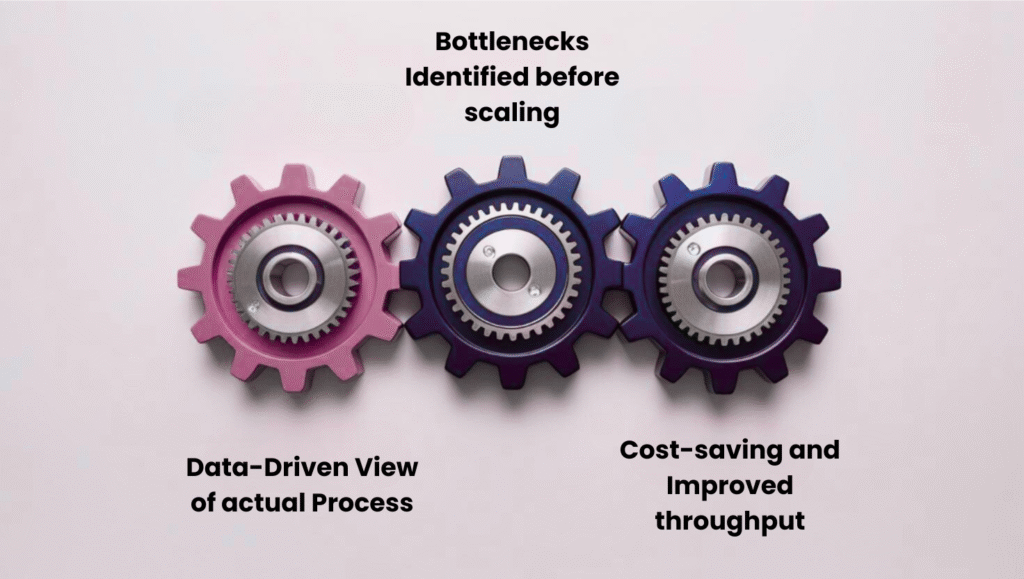

Process mining might sound like something you’d do with pickaxes and shovels, but in the manufacturing world, it’s about using technology to dig into your operational data and uncover hidden inefficiencies. Think of it as an X-ray for your business processes. Solutions like FUTUROOT are changing the game by helping companies truly understand and optimize their operations before they even think about scaling.

Unlike traditional business process management, process mining uses actual system data to create accurate visualizations of how your processes really function. These tools analyze event logs from your existing systems to pinpoint inefficiencies, bottlenecks, and compliance issues.

By implementing process mining before scaling, manufacturers can:

- Discover hidden process inefficiencies that would otherwise become magnified.

- Standardize best practices across all operations.

- Create a digital twin of their processes to simulate manufacturing scalability.

- Track improvements with clear, data-driven metrics.

A beverage manufacturer used process mining to eliminate bottlenecks, saving $1 million per packaging line. In another example, 6% of processes were outside limits, and process mining exposed extended quality control times as the issue—leading to a 15.81%–18.8% productivity boost and a 19.73% cost reduction.

3. Supply Chain Diversification and Risk Assessment: Don’t Put All Your Eggs in One Basket

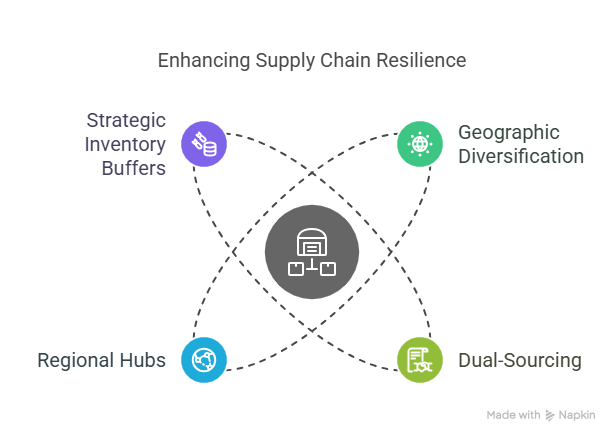

While your industry might feel safe from today’s trade storms, supply chain risk management is essential before you scale. Expansion exposes you to future disruptions, so now’s the time to diversify and build resilience.

Key steps for supply chain risk management:

- Geographic diversification of suppliers and distribution.

- Dual-sourcing critical components.

- Developing regional hubs to reduce logistics vulnerabilities.

- Strategic inventory buffers for essential materials.

Companies practicing supply chain risk management recover 40% faster from disruptions. Experts say supply chain diversification will have one of the highest impacts on supply chain strategies, with 81% of manufacturers pursuing multiple or regional suppliers.

4. Automation Strategy Development: Let the Robots Do the Heavy Lifting

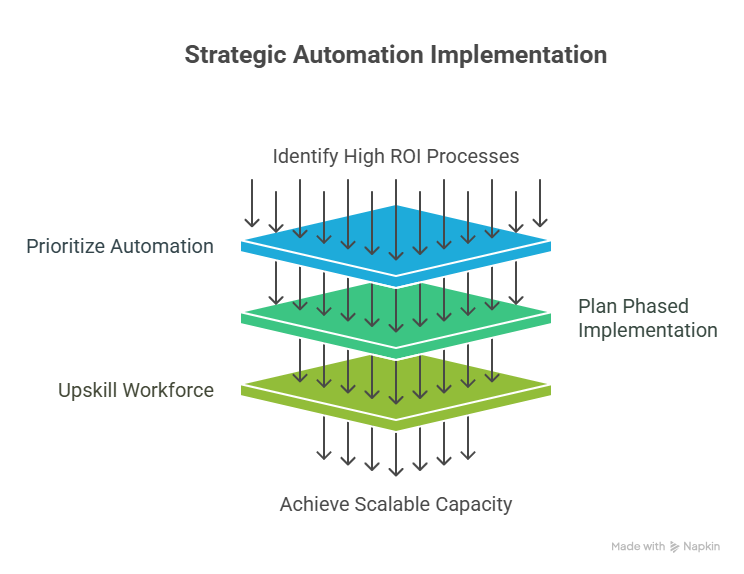

Automation is no longer just about reducing headcount—it’s about enabling manufacturing scalability and improving consistency. Develop a scalable automation plan that aligns with your goals.

Focus your automation on:

- High-ROI areas.

- Phased rollouts starting with critical processes.

- SOPs tailored for automated environments.

- Upskilling your workforce for future roles.

Strategic automation can result in 45% faster scaling, with 23% fewer quality issues. The automation market is projected to grow at 9.7% CAGR till 2030, and AI-led automation could boost productivity by 40% by 2035.

5. Data Integration and Analytics Infrastructure: Turning Raw Data into Insight

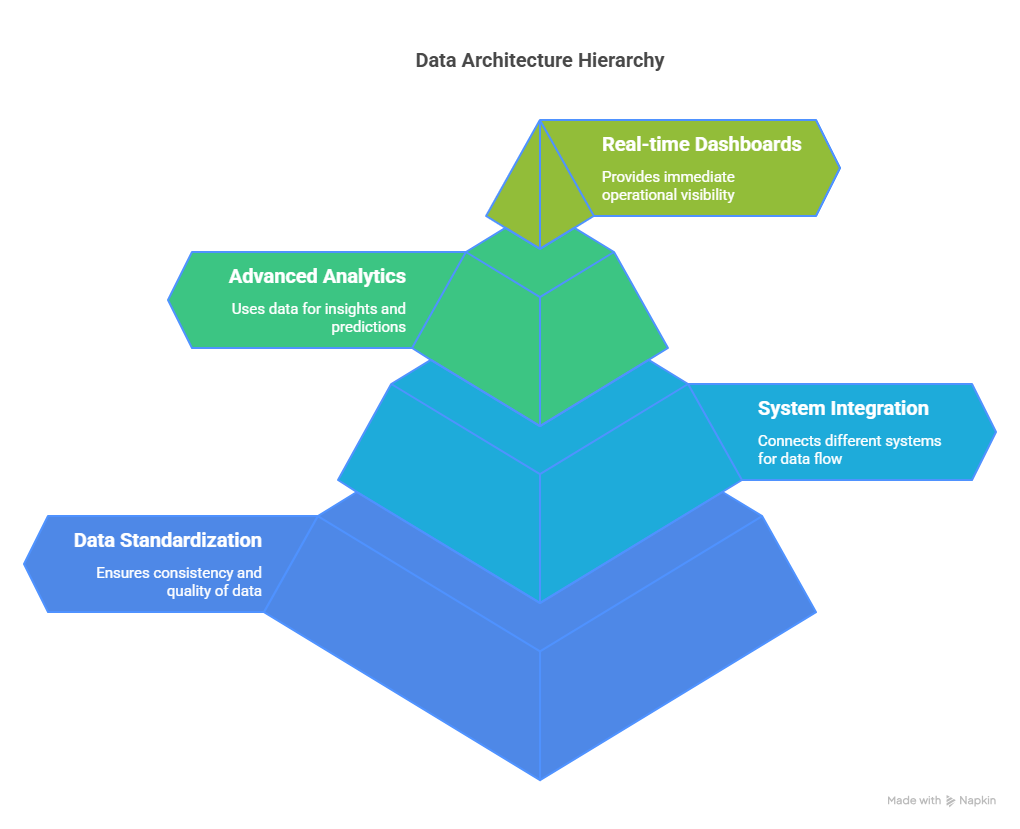

As your company grows, information silos become major blockers. Building a real-time data integration framework is essential to supply chain optimization and smart decision-making.

Elements of data integration:

- Standardized definitions and governance.

- Connectivity between operational and IT systems.

- Predictive analytics to uncover trends and risks.

- Real-time dashboards for actionable visibility.

Companies with strong data integration report 58% more visibility and 41% faster market response. The data integration market is expected to grow at a 13.8% CAGR, driven by the need for real-time analytics.

Conclusion: Preparation is the Ultimate Key to Conquering Chaos

Today’s chaos in global trade is an open door for manufacturers ready to scale intelligently. Those who prepare through ERP systems for supply chain optimization, process mining, automation, supply chain risk management, and robust data integration will thrive.

The winners will not be the biggest or fastest—but the most adaptable. Treat these five hidden keys as the pillars of supply chain optimization, and you’ll be positioned not just to survive disruption—but to lead the charge through it.