Fact-Based Inventory Process Discovery

About this Project

- Client: Global enterprise in Food & Beverage Distribution

- Industry: Food & Beverage Distribution

- Focus Area: SAP Vistex Implementation – Inventory Management

The Challenge

The client, a leading European food service distributor, embarked on a critical project to implement SAP Vistex. However, the company faced a significant hurdle: its existing inventory management system was over 20 years old. Due to its age and extensive use, no one in the organization had a complete, accurate understanding of all the real-world inventory scenarios that had developed over time

Decades of accumulated complexity created serious questions for leadership:

- How could they ensure a smooth and controlled transformation without full visibility into their current processes?

- What were the actual process flows and variations in inventory movement?

- Which of the numerous inventory movement types were truly active, and which were obsolete legacy configurations?

- How did these hidden processes impact forecasting models and business operations?

A lack of factual insights could lead to unnecessary customization, wasted testing, and major disruptions during the SAP Vistex rollout. Leadership needed objectivity, clarity, and factual insights — not assumptions or guesswork.

Why FUTUROOT?

The client faced a 20-year-old, complex inventory system with limited visibility, making a controlled SAP Vistex transformation risky. FUTUROOT delivered clarity, speed, and confidence by:

FUTUROOT delivered clarity, speed, and confidence by:

- Uncovering Hidden Processes — Revealed all active and inactive inventory movement types.

- Quantifying Variants — Mapped 87 scenarios versus 12 known, enabling harmonization.

- Reducing Risk and Waste — Highlighted redundant processes and unnecessary testing.

- Providing a Fact-Based Roadmap — Delivered dashboards and actionable metrics for data-driven decisions.

This approach transformed what could have been a lengthy, high-risk inventory transformation into a rapid, evidence-backed, and controlled process.

Our Approach:

Using FUTUROOT’s advanced toolset, the client gained a transparent understanding of their inventory management landscape:

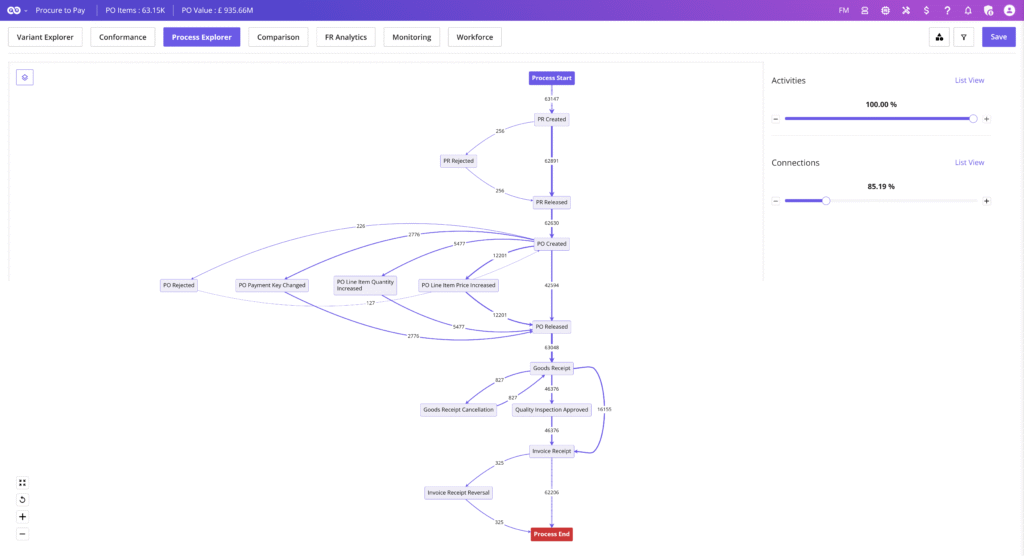

Process Explorer

Analysed 98% of all inventory transactions, distinguishing active from inactive movement types. This eliminated obsolete processes, reducing unnecessary customisation, testing effort, and risk.

Variant Explorer

The analysis identified 87 inventory variants versus 12 previously known, enabling harmonization, cutting 45% of redundancies, and providing full visibility into all processes.

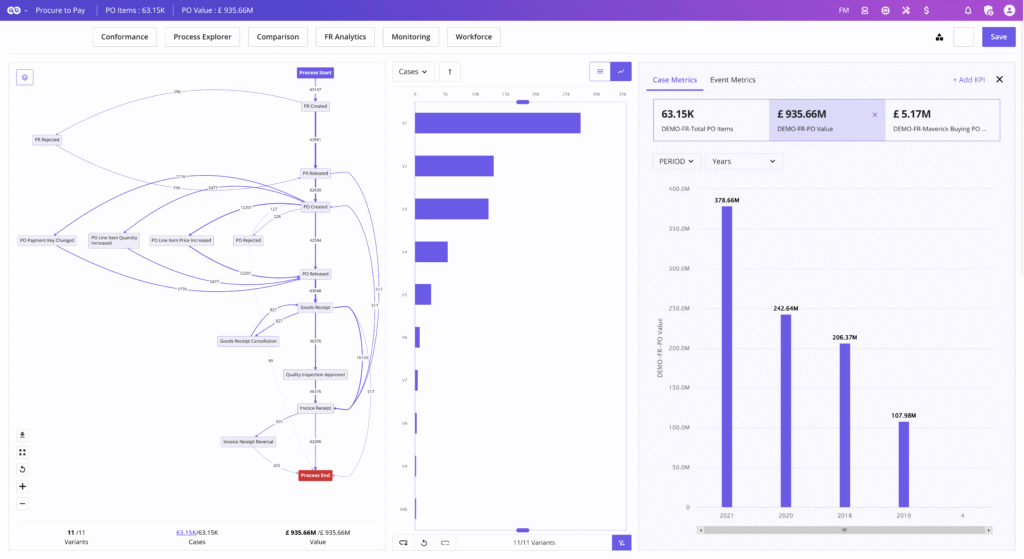

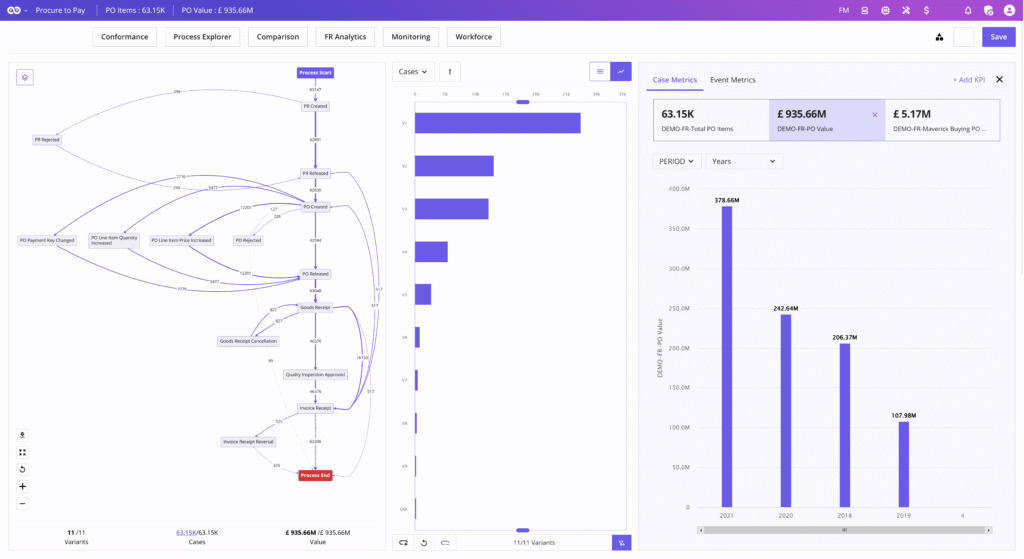

KPI Analysis

Addressing bottlenecks cut exception rates from 22% to 9% and reduced stock reconciliation cycle times by 30%. Process frequency was quantified and linked to forecasting, enabling data-driven updates.

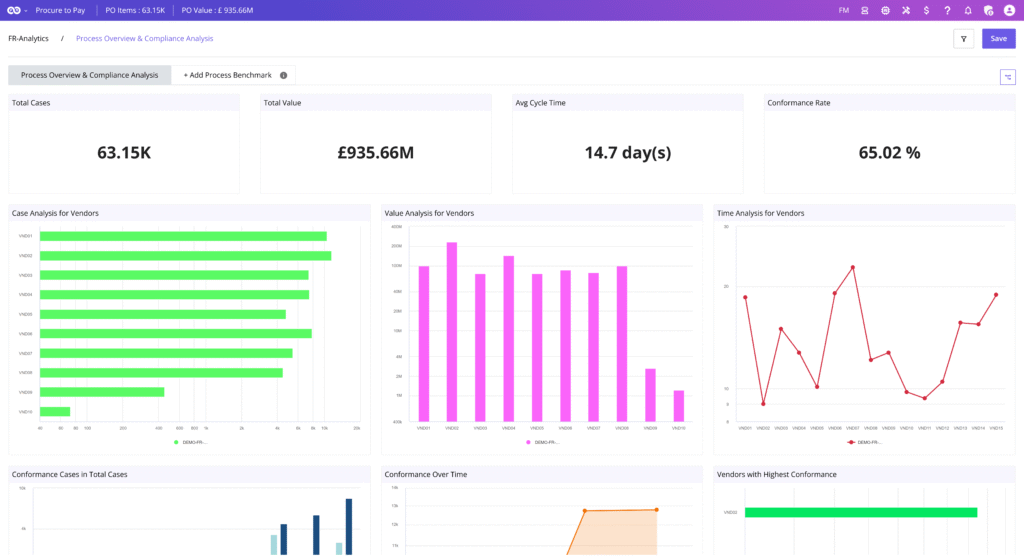

FUTUROOT Analytics

FUTUROOT integrated findings into interactive dashboards, presenting process variations, movement types, and key KPIs in a clear, executive-friendly view.

Additional Impact

Retiring 15% of inactive material codes improved data cleanliness, while reducing test case volume by 35% saved six weeks of UAT effort.

Business Outcomes Delivered

FUTUROOT transformed what could have been a prolonged, high-risk guesswork exercise into a rapid, evidence-backed strategic decision:

Inventory Scenarios Mapped

All active and inactive inventory scenarios were identified, providing a complete, fact-based blueprint for transformation..

Redundant Process Reduction

Harmonisation eliminated nearly half of unnecessary process variants, reducing complexity and risk.

Faster Cycle Times

Stock reconciliation and inventory processes were streamlined cutting cycle times from 10 to 7 days.

Reduced Test Case Volume

UAT effort was reduced by over a third, saving six weeks of testing and accelerating the rollout..

“FUTUROOT gave us the transparency we needed to make a confident transformation decision. Instead of opinions, we had the facts in front of us — fast.”

Client Leadership Feedback