Process Discovery Within The Transformation Journey

Cutting Through Inventory Complexity

for Transformation Success

In major ERP transformations, hidden complexity in inventory management is a silent threat. Over decades, processes multiply, variations creep in, and unused configurations linger. When it’s time to implement a new system like SAP Vistex, these blind spots can drive up costs, slow down testing, and compromise go-live readiness.

FUTUROOT eliminates that uncertainty. By mining SAP event logs, we reveal how inventory really works — every flow, every movement type, every exception. What was invisible becomes clear, giving leaders the confidence to:

- See the full scope of inventory scenarios.

- Separate what’s active from what’s obsolete.

- Focus customization and testing only where it matters.

- Build a cleaner, faster path to transformation.

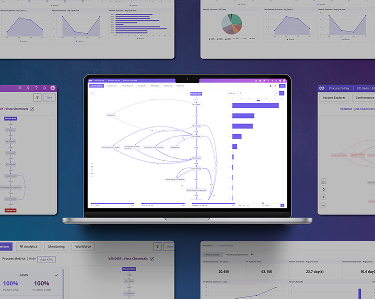

See FUTUROOT in Action

Discover how a leading UK foodservice distributor used FUTUROOT to surface decades of hidden inventory processes and build a fact-based foundation for its SAP Vistex implementation. The company faced a major challenge: its 20-year-old inventory system had become a black box, with only 12 documented scenarios and little clarity on which processes were active, redundant, or obsolete. Flying blind into Vistex risked wasted customization, bloated testing, and disruption at go-live.

FUTUROOT brought transparency. By uncovering 87 unique process variants—and eliminating 45% of redundant ones—the distributor finally saw how inventory really ran. Exception rates dropped from 22% to 9%, stock reconciliation cycles sped up by 30%, and test scope shrank by 35%, saving six weeks of UAT effort. Instead of opinions, this foodservice leader built its transformation on evidence—reducing risk, accelerating delivery, and strengthening governance..